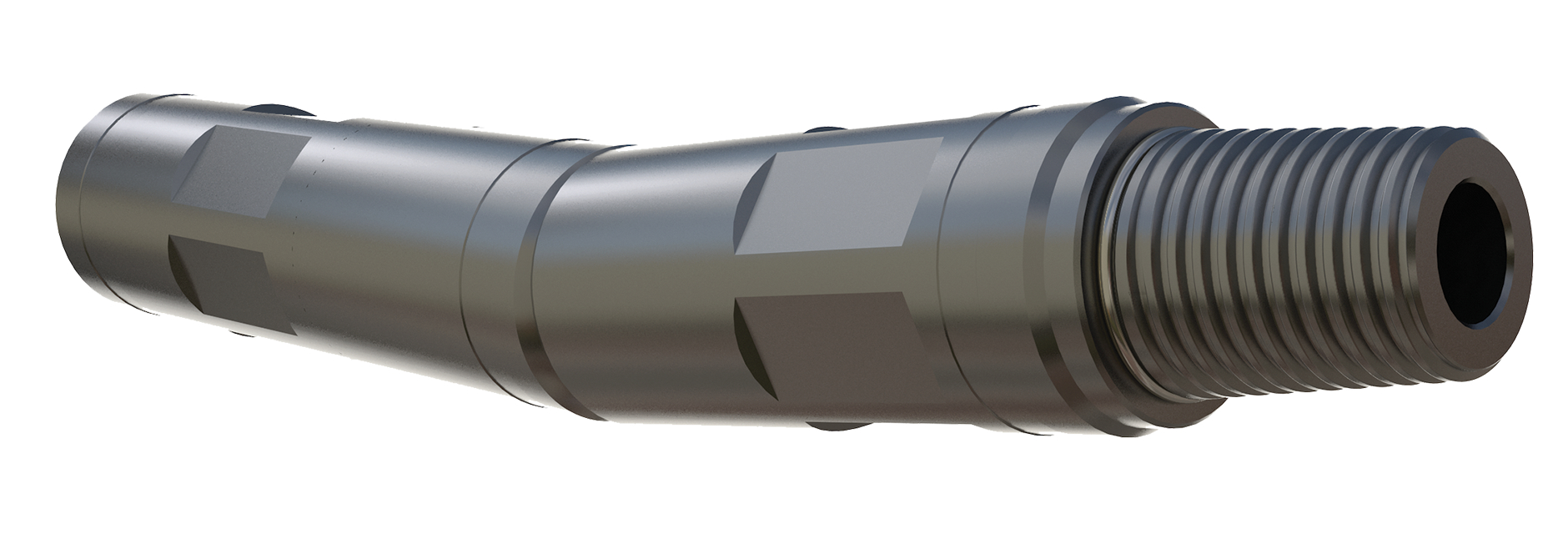

Configuring a Torque-Thru Knuckle Joint within the BHA enables it to pass unrestricted over nipple shoulders, tubing crossovers and other points where a rigid BHA may encounter difficulty. An internal hexagonal profile prevents the ball joint from rotating within the socket therefore providing the torque-thru capability required for use in conjunction with down hole motors, etc.

TOOL APPLICATIONS:

To provide a point of flexibility within a Coiled Tubing BHA whilst maintaining a torque-thru capability.

DESIGN FEATURES & BENEFITS:

Large thru bore

Torque-thru ball joint

Available in a range of sizes to suit industry standard BHA’s

10 degree deflection angle from centre line

Connection options to suit customer requirements

Simple, robust design ensuring ease of operation for the end user

Selected components QPQ treated

Hexagonal flats for safe make-up & break-out

Corrosion resistant materials

Assembly Part No. Actual OD Maximum ID Make up Length

104-1500-XXX-RX 1.500" 0.500" 10.45"

104-1687-XXX-RX 1.687" 0.656" 11.00"

104-1750-XXX-RX 1.750" 0.656" 11.00"

104-2125-XXX-RX 2.125" 0.787" 12.13"

104-2250-XXX-RX 2.250" 0.787" 12.13"

104-2375-XXX-RX 2.375" 0.875" 13.38"

104-2875-XXX-RX 2.875" 1.187" 14.82"

104-3125-XXX-RX 3.125" 1.187" 14.90"

TOOL APPLICATIONS:

To provide a point of flexibility within a Coiled Tubing BHA whilst maintaining a torque-thru capability.

DESIGN FEATURES & BENEFITS:

Large thru bore

Torque-thru ball joint

Available in a range of sizes to suit industry standard BHA’s

10 degree deflection angle from centre line

Connection options to suit customer requirements

Simple, robust design ensuring ease of operation for the end user

Selected components QPQ treated

Hexagonal flats for safe make-up & break-out

Corrosion resistant materials

Assembly Part No. Actual OD Maximum ID Make up Length

104-1500-XXX-RX 1.500" 0.500" 10.45"

104-1687-XXX-RX 1.687" 0.656" 11.00"

104-1750-XXX-RX 1.750" 0.656" 11.00"

104-2125-XXX-RX 2.125" 0.787" 12.13"

104-2250-XXX-RX 2.250" 0.787" 12.13"

104-2375-XXX-RX 2.375" 0.875" 13.38"

104-2875-XXX-RX 2.875" 1.187" 14.82"

104-3125-XXX-RX 3.125" 1.187" 14.90"