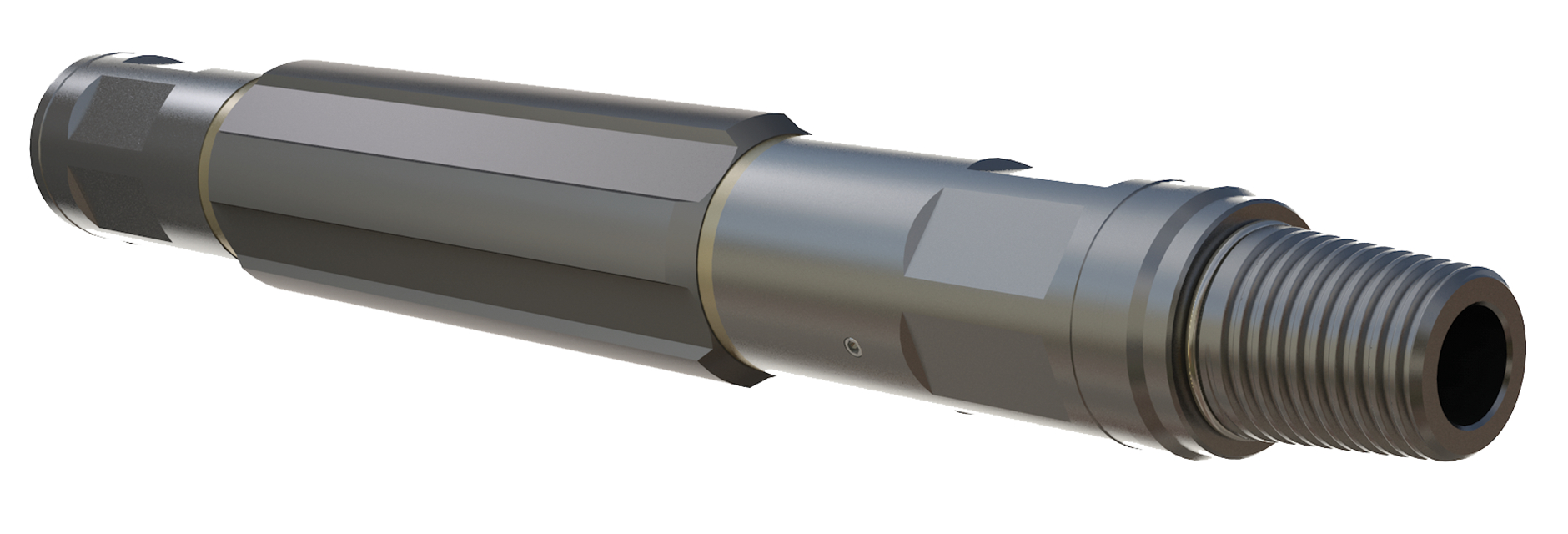

The Non-Rotating Stabiliser mandrel and sleeve can rotate freely and independently of each other whilst the milled flutes along the length of the sleeve provide an adequate bypass path for fluid and cuttings during operations. The stabiliser sleeves can be easily interchanged to suit the working ID whilst utilising the same mandrel for ease of use and inventory reduction.

TOOL APPLICATIONS:

To centralise and stabilise a Coiled Tubing BHA during operations such as milling, cutting or applications where a down hole motor is deployed.

DESIGN FEATURES & BENEFITS:

Interchangeable sleeves for operational flexibility and inventory reduction

Phosphor bronze bearings for component wear reduction

Available in a range of sizes to suit industry standard Coiled Tubing BHA’s

Large thru bore

Simple, robust design ensuring ease of operation for the end user

Selected components QPQ treated

Hexagonal flats for safe make-up & break-out

Connection options to suit customer requirements

Corrosion resistant material Assembly

Assembly Part No. Actual OD (Excl. Sleeve) Maximum ID Make up Length

114-1687-XXX-RX 1.687" 0.652" 15.65"

114-1750-XXX-RX 1.750" 0.652" 15.65"

114-2125-XXX-RX 2.125" 0.875" 16.50"

114-2875-XXX-RX 2.875" 1.500" 20.00"

TOOL APPLICATIONS:

To centralise and stabilise a Coiled Tubing BHA during operations such as milling, cutting or applications where a down hole motor is deployed.

DESIGN FEATURES & BENEFITS:

Interchangeable sleeves for operational flexibility and inventory reduction

Phosphor bronze bearings for component wear reduction

Available in a range of sizes to suit industry standard Coiled Tubing BHA’s

Large thru bore

Simple, robust design ensuring ease of operation for the end user

Selected components QPQ treated

Hexagonal flats for safe make-up & break-out

Connection options to suit customer requirements

Corrosion resistant material Assembly

Assembly Part No. Actual OD (Excl. Sleeve) Maximum ID Make up Length

114-1687-XXX-RX 1.687" 0.652" 15.65"

114-1750-XXX-RX 1.750" 0.652" 15.65"

114-2125-XXX-RX 2.125" 0.875" 16.50"

114-2875-XXX-RX 2.875" 1.500" 20.00"