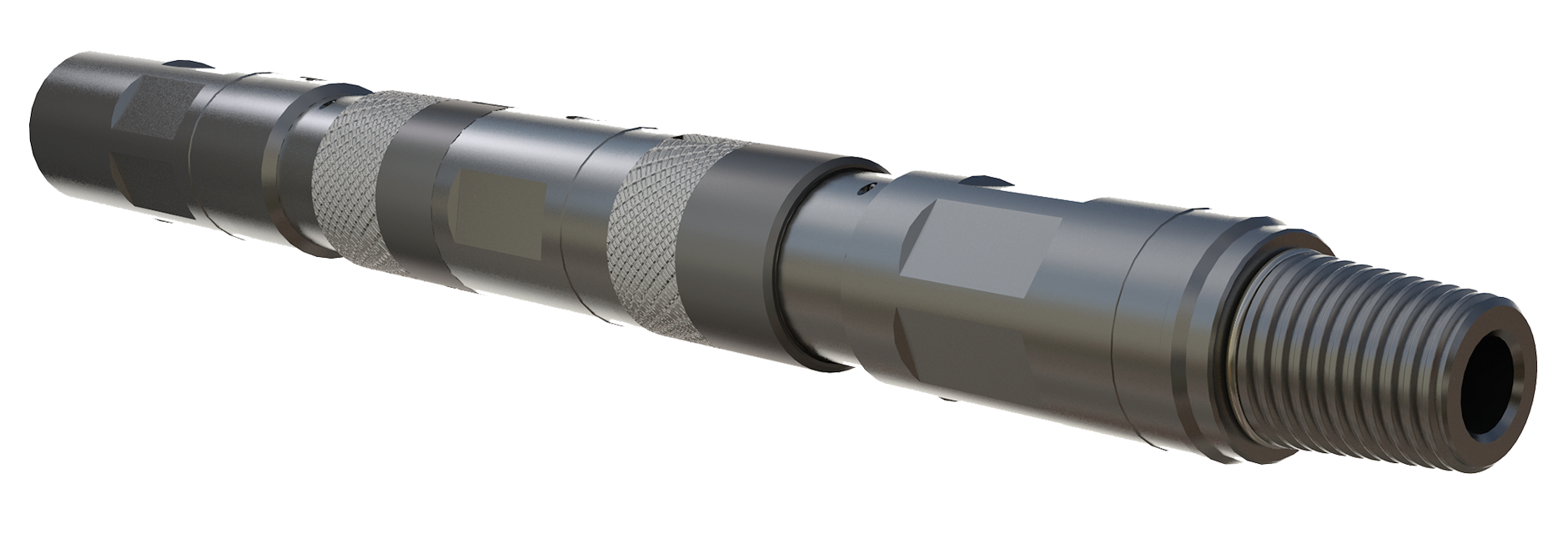

The Dual Isolation Valve is configured directly above a deployment bar and beneath a deployment connector in a lower BHA section. Using the BOP pipe rams to secure and seal across the deployment bar, in the “Closed” position, the LiMAR® Dual Isolation Valve provides a double barrier whilst connecting the upper section of the BHA. Once the BHA has been assembled and integrity tested, the Dual Isolation Valve can be locked into the “Open” position ready for the riser to be stabbed on, ready for operations to commence.

TOOL APPLICATIONS:

Used to isolate well pressure during Coiled Tubing BHA deployment operations

DESIGN FEATURES & BENEFITS:

Dual sealing ball valves provide double mechanical barrier

Ball Valves operated using allen key

Bi-directional seal assemblies hold pressure from above & below

Ball-Check type bleed ports for safe equalisation

Available in a range of sizes to suit industry standard Coiled Tubing BHA’s

Locking Sleeve with easily identifiable Open & Closed Positions

Connection options to suit customer requirements

Simple, robust design ensuring ease of operation for the end user

Selected components QPQ treated

Hexagonal flats for safe make-up & break-out

Corrosion resistant materials

Assembly Part No. Actual OD Minimum ID Make up Length

213-1687-XXX-RX 1.687" 0.600" 17.98"

213-1750-XXX-RX 1.750" 0.600" 18.00"

213-2125-XXX-RX 2.125" 0.787" 19.18"

213-2875-XXX-RX 2.875" 1.000" 20.56"

TOOL APPLICATIONS:

Used to isolate well pressure during Coiled Tubing BHA deployment operations

DESIGN FEATURES & BENEFITS:

Dual sealing ball valves provide double mechanical barrier

Ball Valves operated using allen key

Bi-directional seal assemblies hold pressure from above & below

Ball-Check type bleed ports for safe equalisation

Available in a range of sizes to suit industry standard Coiled Tubing BHA’s

Locking Sleeve with easily identifiable Open & Closed Positions

Connection options to suit customer requirements

Simple, robust design ensuring ease of operation for the end user

Selected components QPQ treated

Hexagonal flats for safe make-up & break-out

Corrosion resistant materials

Assembly Part No. Actual OD Minimum ID Make up Length

213-1687-XXX-RX 1.687" 0.600" 17.98"

213-1750-XXX-RX 1.750" 0.600" 18.00"

213-2125-XXX-RX 2.125" 0.787" 19.18"

213-2875-XXX-RX 2.875" 1.000" 20.56"