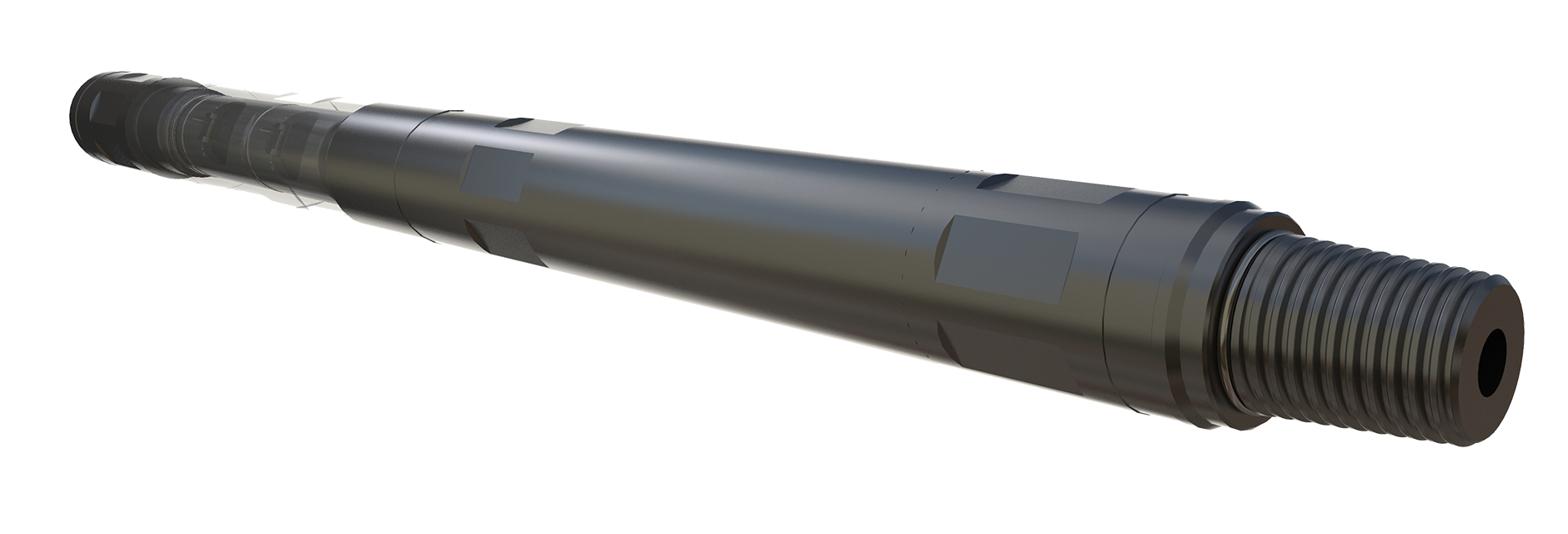

The tool is configured so that the flapper valves are held open during normal operations thus allowing circulation from the annulus to the Coiled Tubing string. In the event of an emergency, or as part of the planned work-scope, a drop ball can be launched to shift a piston which activates the flapper valves to provide a positive barrier from well-bore fluids.

The cartridge type design allows fast and efficient redress with simple removal and replacement of the flapper cartridge assembly at surface.

TOOL APPLICATIONS:

Reverse circulating clean outs

DESIGN FEATURES & BENEFITS:

Maintains flow path following activation to allow BHA components below to be operated

Corrosion resistant materials

Connection options to suit customer requirements

Simple, robust design ensuring ease of operation for the end user

Selected components QPQ treated

Hexagonal flats for safe make-up & break-out

Assembly Part No. Actual OD Maximum ID Make up Length

193-2125-XXX-RX 2.125" 0.562" 26"

193-2375-XXX-RX 2.375" 0.562" 26"

193-2875-XXX-RX 2.875" 0.875" 33"

The cartridge type design allows fast and efficient redress with simple removal and replacement of the flapper cartridge assembly at surface.

TOOL APPLICATIONS:

Reverse circulating clean outs

DESIGN FEATURES & BENEFITS:

Maintains flow path following activation to allow BHA components below to be operated

Corrosion resistant materials

Connection options to suit customer requirements

Simple, robust design ensuring ease of operation for the end user

Selected components QPQ treated

Hexagonal flats for safe make-up & break-out

Assembly Part No. Actual OD Maximum ID Make up Length

193-2125-XXX-RX 2.125" 0.562" 26"

193-2375-XXX-RX 2.375" 0.562" 26"

193-2875-XXX-RX 2.875" 0.875" 33"