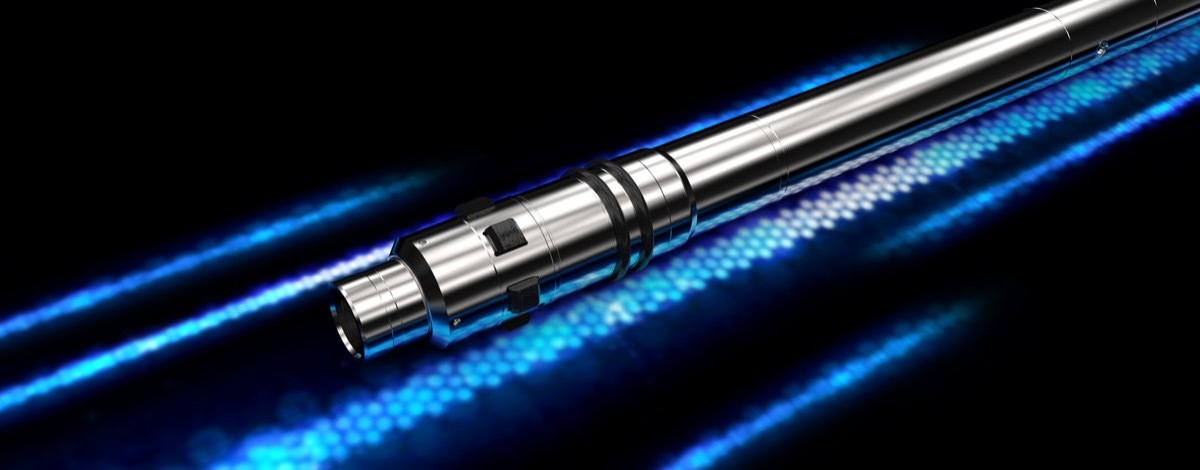

To complement the range of annulus bore Hybrid Plugs, Oilenco has developed a range of Hybrid Plugs for the production bore which boast the same “best of both worlds” approach to design utilised by the smaller annulus plugs.

The Oilenco Hybrid Plug range combines the mechanical simplicity of a Nipple set blanking plug with the integrity assurance of a bridge plug thanks to its innovative seal design.

For example, during a tree change out, the production bore require the installation of either a blanking plug (set in a nipple profile) or a bridge plug. Either method has distinct advantages and disadvantages. Blanking plugs have the obvious advantage of simplicity, both in terms of deployment and method of sealing (V Packings). The disadvantage of a pressure test from above on a V packing is that it does not prove pressure integrity from below. Alternatively, a bridge plug features an expanding element, therefore a pressure test from above is reasonable assurance of pressure integrity from below. The disadvantage of setting a bridge plug is that they normally require the use of relatively sophisticated setting equipment and skilled personnel.

The Oilenco Hybrid Plug is set and retrieved on slickline and uses an existing landing nipple profile within the tubing hanger. Using a dedicated mechanical setting tool, the plug is initially locked into the nipple profile.

The Hybrid Plug can also be crossed over to all manner of accessories such as pump open plugs, remotely activated equalising devices to suit different customer requirements.

The Oilenco Hybrid Plug range combines the mechanical simplicity of a Nipple set blanking plug with the integrity assurance of a bridge plug thanks to its innovative seal design.

For example, during a tree change out, the production bore require the installation of either a blanking plug (set in a nipple profile) or a bridge plug. Either method has distinct advantages and disadvantages. Blanking plugs have the obvious advantage of simplicity, both in terms of deployment and method of sealing (V Packings). The disadvantage of a pressure test from above on a V packing is that it does not prove pressure integrity from below. Alternatively, a bridge plug features an expanding element, therefore a pressure test from above is reasonable assurance of pressure integrity from below. The disadvantage of setting a bridge plug is that they normally require the use of relatively sophisticated setting equipment and skilled personnel.

The Oilenco Hybrid Plug is set and retrieved on slickline and uses an existing landing nipple profile within the tubing hanger. Using a dedicated mechanical setting tool, the plug is initially locked into the nipple profile.

The Hybrid Plug can also be crossed over to all manner of accessories such as pump open plugs, remotely activated equalising devices to suit different customer requirements.