Downhole Products Technical team are continually engaged in the research, design, testing and manufacture of a variety of specialist products for customer specific applications, applying many different materials and manufacturing techniques. We continue to introduce innovative products to the market while expanding our portfolio, which include the market leading Spir-O-LizerTM solid body zinc alloy centralizer and the Pen-O-TratorTM reamer shoe products.

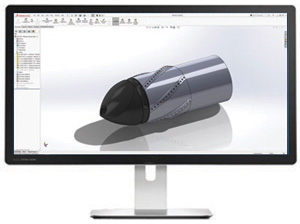

Our commitment to supporting and investing in ‘cutting edge’ technologies has reduced our ‘life cycle’ design process. Our engineering design team utilize the very latest Computer Aided Design (CAD) software to produce technical 3D dimensional modelling, coupled with animation and simulation abilities, this enables us to conceptually prove new products prior to manufacture. We also have in-house 3D printing capability to aid physical product representation and prove new concept designs.

Downhole Products proudly utilises and provides technical and diverse testing capabilities at many of our global locations. Significant investment has been focussed on ensuring Downhole Products have an infrastructure to support the development of industry leading products, including:

API 10D test rigs for start, running and restoring force

Additional compression / load testing rigs to exceed API 10D

Lateral / end load testing on solid body centralizers and casing shoe products

Float equipment pressure testing in accordance with API RP 10F IIIC

Cement batch sampling and testing in accordance with BS EN 12390

Cable protector cable push / pull test rig

Stop collar testing facilities meeting API 10D II requirements

Bespoke client specific test capabilities

Our commitment to supporting and investing in ‘cutting edge’ technologies has reduced our ‘life cycle’ design process. Our engineering design team utilize the very latest Computer Aided Design (CAD) software to produce technical 3D dimensional modelling, coupled with animation and simulation abilities, this enables us to conceptually prove new products prior to manufacture. We also have in-house 3D printing capability to aid physical product representation and prove new concept designs.

Downhole Products proudly utilises and provides technical and diverse testing capabilities at many of our global locations. Significant investment has been focussed on ensuring Downhole Products have an infrastructure to support the development of industry leading products, including:

API 10D test rigs for start, running and restoring force

Additional compression / load testing rigs to exceed API 10D

Lateral / end load testing on solid body centralizers and casing shoe products

Float equipment pressure testing in accordance with API RP 10F IIIC

Cement batch sampling and testing in accordance with BS EN 12390

Cable protector cable push / pull test rig

Stop collar testing facilities meeting API 10D II requirements

Bespoke client specific test capabilities