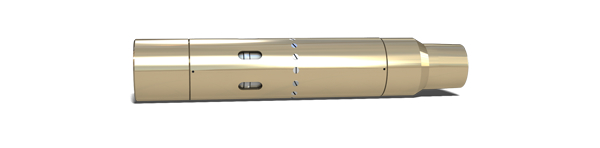

The EZ-Port™ is an efficient, cost-effective openhole frac sleeve with erosion resistant millable ball seats. The sleeve allows operators to treat multiple stages with a continuous pump time and reliable ball actuation.

The EZ-Port™ offers up to 31 independently treated stages and its short length and small OD enable it to be easily installed in horizontal wells. The tool’s torque-locked internal components allow seat to be milled quickly in the open or closed position.

The EZ-Port™ is one of Peak’s variety of frac sleeve options. It can be run with the several different zonal isolation options, including mechanical and swellable packers. Initial equipment costs as well as operating expenses, such as water, frac fluids, and hydraulic horsepower, are reduced by utilizing this economical solution for multistage stimulation.

The EZ-Port™ can also be run as part of a fully retrievable system, making it an ideal solution for acidizing and sand frac restimulation projects. The sleeve may be used for additional applications such as a standard tubing drain or to open up the annulus to the tubing for pressure equalization.

PRODUCT HIGHLIGHTS

Increase efficiencies by saving time and money on completion operations

Minimize operational risk

Quick, easy installation with small OD and short overall length

Ensure desired frac placement with proprietary ball development and seat design

Economic design maximizes profits

DESIGN FEATURES

350°F Standard Rating - HPHT Adaptable

10K Burst Rating

Full ID access after mill out

Anti-torque system allows for mill out in open or closed position

Erosion resistant ball seats and reliable shear design for high frac rates

31 Stage System Design with HydroPort™

LTC, BTC, EU, NU, and premium thread options available

The EZ-Port™ offers up to 31 independently treated stages and its short length and small OD enable it to be easily installed in horizontal wells. The tool’s torque-locked internal components allow seat to be milled quickly in the open or closed position.

The EZ-Port™ is one of Peak’s variety of frac sleeve options. It can be run with the several different zonal isolation options, including mechanical and swellable packers. Initial equipment costs as well as operating expenses, such as water, frac fluids, and hydraulic horsepower, are reduced by utilizing this economical solution for multistage stimulation.

The EZ-Port™ can also be run as part of a fully retrievable system, making it an ideal solution for acidizing and sand frac restimulation projects. The sleeve may be used for additional applications such as a standard tubing drain or to open up the annulus to the tubing for pressure equalization.

PRODUCT HIGHLIGHTS

Increase efficiencies by saving time and money on completion operations

Minimize operational risk

Quick, easy installation with small OD and short overall length

Ensure desired frac placement with proprietary ball development and seat design

Economic design maximizes profits

DESIGN FEATURES

350°F Standard Rating - HPHT Adaptable

10K Burst Rating

Full ID access after mill out

Anti-torque system allows for mill out in open or closed position

Erosion resistant ball seats and reliable shear design for high frac rates

31 Stage System Design with HydroPort™

LTC, BTC, EU, NU, and premium thread options available