REDUCES TORQUE AND DRAG

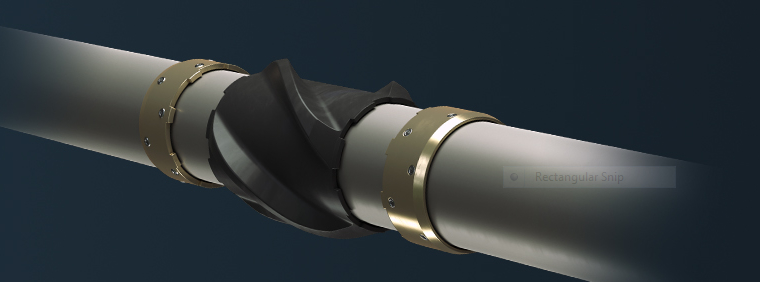

The RotoGLIDE tools are a derivative of the highly successful field proven EzeeGLIDER® with the added feature of drive teeth on the centralizer and drive profiles on the heavy duty stop collars. These features have been tested for wear with applied loads and provide continuous drive while rotating the casing for extended periods in excess of most casing/liner deployment operations. Rubicon RotoGLIDE casing tools provide our industry with the ability to rotate the entire casing string to reduce drag significantly while rotating allowing the ERD envelope to be pushed even further.

MAKING IT BETTER

The RotoGLIDE uses rotation combined with composite material provides a significant reduction in axial friction. It does not increase torque to turn pipe while cementing.

The RotoGLIDE rides over ledges and its short design does not stiffen the string. The RotoGLIDE turns easily around high dog leg severity, toughness and abrasion resistance to address high side forces. The RotoGLIDE offers greater than normal reduction in drag which reduces helical buckling. On high step out wells, the current well construction boundaries are extended. Should casing or completion fail to reach TD, low drag aids are removed from the wellbore. The RotoGLIDE is lightweight, which improves manual handling, is low on start up torque and assists passage through casing exits and multilateral junctions.

FEATURES

Drives each centralizer independently

No difference between static and dynamic friction and low coefficient of friction

Drive profile on stop collars

Available for both uni-directional and bi-directional applications

Proven wear resistance and toughness

High impact resistance

High compressive and tensile strength

Short compact design to fit onto screens

High thermal stability

Ultra-low axial static and dynamic coefficient of friction

The RotoGLIDE tools are a derivative of the highly successful field proven EzeeGLIDER® with the added feature of drive teeth on the centralizer and drive profiles on the heavy duty stop collars. These features have been tested for wear with applied loads and provide continuous drive while rotating the casing for extended periods in excess of most casing/liner deployment operations. Rubicon RotoGLIDE casing tools provide our industry with the ability to rotate the entire casing string to reduce drag significantly while rotating allowing the ERD envelope to be pushed even further.

MAKING IT BETTER

The RotoGLIDE uses rotation combined with composite material provides a significant reduction in axial friction. It does not increase torque to turn pipe while cementing.

The RotoGLIDE rides over ledges and its short design does not stiffen the string. The RotoGLIDE turns easily around high dog leg severity, toughness and abrasion resistance to address high side forces. The RotoGLIDE offers greater than normal reduction in drag which reduces helical buckling. On high step out wells, the current well construction boundaries are extended. Should casing or completion fail to reach TD, low drag aids are removed from the wellbore. The RotoGLIDE is lightweight, which improves manual handling, is low on start up torque and assists passage through casing exits and multilateral junctions.

FEATURES

Drives each centralizer independently

No difference between static and dynamic friction and low coefficient of friction

Drive profile on stop collars

Available for both uni-directional and bi-directional applications

Proven wear resistance and toughness

High impact resistance

High compressive and tensile strength

Short compact design to fit onto screens

High thermal stability

Ultra-low axial static and dynamic coefficient of friction