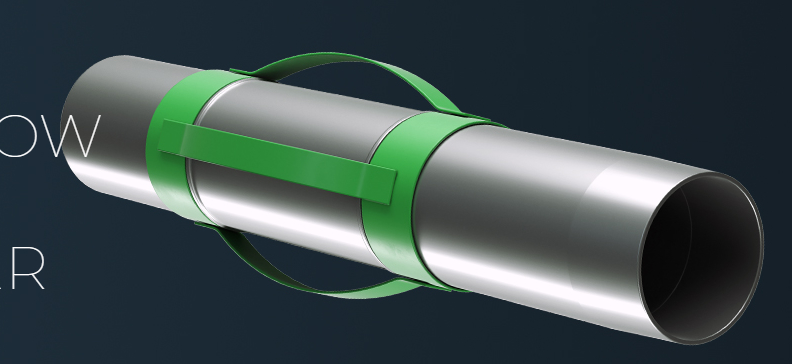

THE TYPE 361 - ROTOBO® INTEGRAL BOW SPRING CENTRALIZER SUB HAS BEEN DESIGNED TO WITHSTAND THE MOST EXTREME DEEPWATER DOWNHOLE CONDITIONS.

Manufactured from seamless mechanical tubing, the Rotobo® is completely customizable to meet or exceed the exact requirements of specific wells and casing strings.

MAKING IT BETTER

The Rotobo is a low cost, customizable tool with the ability to rotate the casing string without damaging the bows or centralizer sub.

The Type 361 - Rotobo® Integral Bow Spring Centralizer Sub is designed for use in deepwater wells where under-reamed hole sections are required. The sub design allows the centralizer to pass through tight annular clearances then open up in the under-reamed section to provide the centralization needed to acquire an adequate cement sheath. The RotoboTM model is well suited for applications where casing rotation is required.

FEATURES

Welded bow spring centralizer installed over integral shoulders which are machined into the sub

Bow springs are installed on the sub in such a manner that they are pulled into or out of the hole reducing the risk of bow deformation

Improved mud removal and cement placement through casing rotation

The bow spring centralizer is free to rotate about the sub’s axis

The threads on the sub are designed to match that of the adjacent casing string for integral connection

The metallurgy and mechanical properties will meet or exceed the specifications of the adjacent casing string

Designs are customizable within the API 5CT specifications to meet well specific clearance limitations

Manufactured from seamless mechanical tubing, the Rotobo® is completely customizable to meet or exceed the exact requirements of specific wells and casing strings.

MAKING IT BETTER

The Rotobo is a low cost, customizable tool with the ability to rotate the casing string without damaging the bows or centralizer sub.

The Type 361 - Rotobo® Integral Bow Spring Centralizer Sub is designed for use in deepwater wells where under-reamed hole sections are required. The sub design allows the centralizer to pass through tight annular clearances then open up in the under-reamed section to provide the centralization needed to acquire an adequate cement sheath. The RotoboTM model is well suited for applications where casing rotation is required.

FEATURES

Welded bow spring centralizer installed over integral shoulders which are machined into the sub

Bow springs are installed on the sub in such a manner that they are pulled into or out of the hole reducing the risk of bow deformation

Improved mud removal and cement placement through casing rotation

The bow spring centralizer is free to rotate about the sub’s axis

The threads on the sub are designed to match that of the adjacent casing string for integral connection

The metallurgy and mechanical properties will meet or exceed the specifications of the adjacent casing string

Designs are customizable within the API 5CT specifications to meet well specific clearance limitations