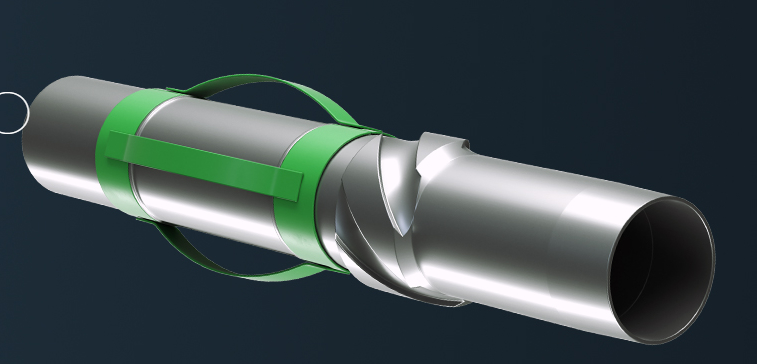

WITH THE ENERGY INDUSTRY’S CHALLENGING PERFORMANCE REQUIREMENTS, TYPE 362 – SUPERCOMBO INTEGRAL CENTRALIZER SUB HAS BEEN DESIGNED TO WITHSTAND THE MOST EXTREME DEEP WATER DOWNHOLE CONDITIONS.

Manufactured from seamless mechanical tubing, the integral is completely customizable to meet or exceed the exact requirements of specific wells and casing strings.

MAKING IT BETTER

The SuperCombo Centralizer sub is well suited for flush joint applications where the operator needs a peace of mind in knowing that the centralizer will not slip on the casing string.

The SuperCombo has the ability to rotate the casing string improves mud removal and cement placement. The solid vanes guarantee a minimum standoff when higher than expected side forces are encountered. The solid vanes also provide protection for the bow spring centralizer. The bow strings are installed on the sub in such a manner that they will be pulled into or out of the hole reducing the risk of bow deformation. The SuperCombo also provides additional fluid agitation when spiral vanes are used.

FEATURES

Welded bow spring centralizer sub installed over integral shoulders machined into the OD of the sub

The bow spring centralizer is free to rotate about the sub’s axis

Machined vanes (either spiral or straight) can be machined above and/or below the bow spring centralizer

The threads on the sub match that of the adjacent casing string for integral connection

The metallurgy and mechanical properties of the sub will meet or exceed specifications of adjacent casing string

Designs are customizable within the API 5CT specifications to meet well specific clearance limitations

Vane dimensions are customizable to increase flow-by area (reduce ECDs) while maintaining standoff for improved mud displacement and cementing

The sub's wall thickness is maximized where possible for optimal burst and collapse ratings

Manufactured from seamless mechanical tubing, the integral is completely customizable to meet or exceed the exact requirements of specific wells and casing strings.

MAKING IT BETTER

The SuperCombo Centralizer sub is well suited for flush joint applications where the operator needs a peace of mind in knowing that the centralizer will not slip on the casing string.

The SuperCombo has the ability to rotate the casing string improves mud removal and cement placement. The solid vanes guarantee a minimum standoff when higher than expected side forces are encountered. The solid vanes also provide protection for the bow spring centralizer. The bow strings are installed on the sub in such a manner that they will be pulled into or out of the hole reducing the risk of bow deformation. The SuperCombo also provides additional fluid agitation when spiral vanes are used.

FEATURES

Welded bow spring centralizer sub installed over integral shoulders machined into the OD of the sub

The bow spring centralizer is free to rotate about the sub’s axis

Machined vanes (either spiral or straight) can be machined above and/or below the bow spring centralizer

The threads on the sub match that of the adjacent casing string for integral connection

The metallurgy and mechanical properties of the sub will meet or exceed specifications of adjacent casing string

Designs are customizable within the API 5CT specifications to meet well specific clearance limitations

Vane dimensions are customizable to increase flow-by area (reduce ECDs) while maintaining standoff for improved mud displacement and cementing

The sub's wall thickness is maximized where possible for optimal burst and collapse ratings