Managed Pressure Drilling (MPD) is an adaptive process used to more precisely control the annular pressure profile throughout the wellbore while drilling.

Converting conventional atmospheric drilling to a closed circulating loop system enables the driller to optimize mud weight and rate of penetration (ROP), more quickly detect influx and fluid loss, and discriminate wellbore ballooning and breathing. This results in lower mud product cost, less stuck pipe, and potentially fewer casing strings.

The MPD process is executed by controlling flow conditions to maintain bottom-hole pressure according to a modeled pore pressure and fracture gradient drilling window. While the benefits of conventional MPD techniques are well known offshore, the economics of engineering, mobilization and rig-up, and additional specialized personnel requirements are not supported in cost-sensitive drilling programs such as unconventional land drilling.

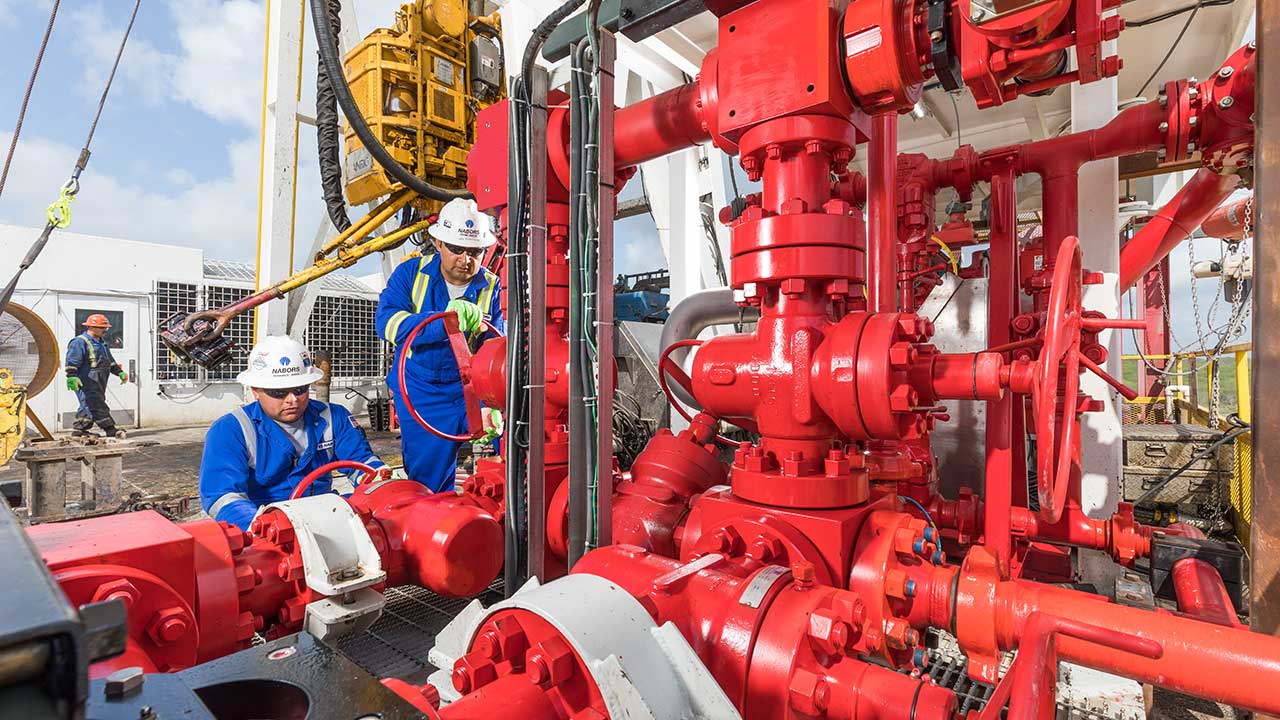

Nabors’ fit-for-purpose MPD equipment and integrated rig services enables a new concept to leverage today’s advanced land rig infrastructure including drives, manifolds, tanks, pumps, and gas handling equipment. Engineering and integrating MPD capabilities into the rig with unique automated workflows unlocks advantages in capital requirements, eliminates the need for pre-job surveys and engineering, and minimizes high mobilization and rig-up costs.

Through the advanced integration and automation of MPD services, the need for third-party service providers is also eliminated. Benefits include increased safety, less HSE exposure, lower cost, reduced pad footprint, more efficient rig moves, and more transparent performance analytics. For all of these reasons, scalability of MPD services is now more cost-effective for land drilling operations.

Converting conventional atmospheric drilling to a closed circulating loop system enables the driller to optimize mud weight and rate of penetration (ROP), more quickly detect influx and fluid loss, and discriminate wellbore ballooning and breathing. This results in lower mud product cost, less stuck pipe, and potentially fewer casing strings.

The MPD process is executed by controlling flow conditions to maintain bottom-hole pressure according to a modeled pore pressure and fracture gradient drilling window. While the benefits of conventional MPD techniques are well known offshore, the economics of engineering, mobilization and rig-up, and additional specialized personnel requirements are not supported in cost-sensitive drilling programs such as unconventional land drilling.

Nabors’ fit-for-purpose MPD equipment and integrated rig services enables a new concept to leverage today’s advanced land rig infrastructure including drives, manifolds, tanks, pumps, and gas handling equipment. Engineering and integrating MPD capabilities into the rig with unique automated workflows unlocks advantages in capital requirements, eliminates the need for pre-job surveys and engineering, and minimizes high mobilization and rig-up costs.

Through the advanced integration and automation of MPD services, the need for third-party service providers is also eliminated. Benefits include increased safety, less HSE exposure, lower cost, reduced pad footprint, more efficient rig moves, and more transparent performance analytics. For all of these reasons, scalability of MPD services is now more cost-effective for land drilling operations.