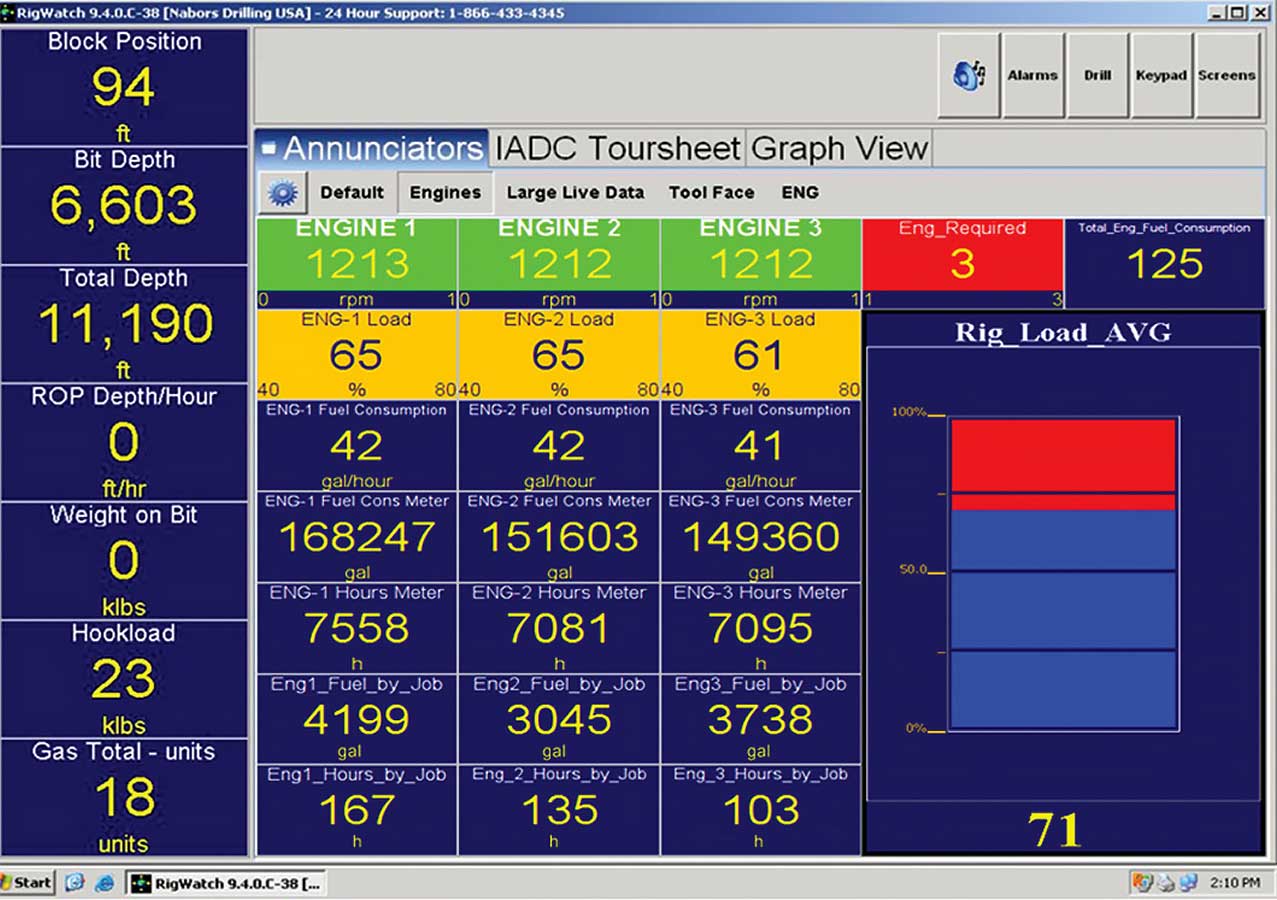

The inability to monitor fuel use and engine load in real-time across multiple engines can lead to unnecessary equipment usage and higher fuel costs. The Fuel Management system provides data that helps rig personnel understand how fuel is being consumed. This, in turn, reduces overall engine fuel usage to improve bottom line costs and achieve a new level of drilling efficiency.

Through rig site screens, personnel can see exactly how many engines are required during rig-up, drilling, logging, cementing and other phases of well operations. The potential savings could be as much as 25 to 35 percent, including as much as 1,000 gallons of fuel savings a day, maintenance savings of up to $1,000 a day and potential carbon dioxide (CO2) reduction of 2,000 pounds per day.

In addition, the Fuel Management system helps conserve fuel and reduce emissions. Each hour an engine is not running equates to a savings of $12.34 in maintenance costs and $22.20 in CO2 carbon credits.

The Fuel Management system also reduces maintenance and operating costs as rig engines are run at the optimal loads.

Through rig site screens, personnel can see exactly how many engines are required during rig-up, drilling, logging, cementing and other phases of well operations. The potential savings could be as much as 25 to 35 percent, including as much as 1,000 gallons of fuel savings a day, maintenance savings of up to $1,000 a day and potential carbon dioxide (CO2) reduction of 2,000 pounds per day.

In addition, the Fuel Management system helps conserve fuel and reduce emissions. Each hour an engine is not running equates to a savings of $12.34 in maintenance costs and $22.20 in CO2 carbon credits.

The Fuel Management system also reduces maintenance and operating costs as rig engines are run at the optimal loads.