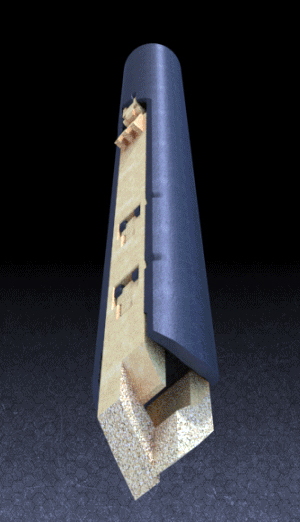

The Medusa™ VS cutting technology was developed to meet the need for “single trip section milling”, thus saving operators time and cost. Our breakthrough technology allows operators to perform section milling of windows and guarantees that the outer casing string is left unharmed even when the casing strings are eccentric. The Medusa™ self centralizes inside the string of casing it is milling so that eccentric casing strings do not matter.

New Patented design for casing sizes 7” out to 30”

Single Trip completion = less time = cost savings

Multifaceted tool - can function as a single string section mill, a dual string section mill or a pilot milling tool.

Designed cutter technology ensures NO HARM to outer string of casing.

Designed cutter technology provides real time data as to rate of penetration and cutting depth based on cutter wear.

Medusa™ blade lengths can be manufactured specifically for long window lengths of 100’+.

Robust tool designs and high tensile strengths make the Medusa deep water ready.

Medusa™ can be custom designed to fit your wells specific needs for perfect fit and performance.

New Patented design for casing sizes 7” out to 30”

Single Trip completion = less time = cost savings

Multifaceted tool - can function as a single string section mill, a dual string section mill or a pilot milling tool.

Designed cutter technology ensures NO HARM to outer string of casing.

Designed cutter technology provides real time data as to rate of penetration and cutting depth based on cutter wear.

Medusa™ blade lengths can be manufactured specifically for long window lengths of 100’+.

Robust tool designs and high tensile strengths make the Medusa deep water ready.

Medusa™ can be custom designed to fit your wells specific needs for perfect fit and performance.